Averting the Path to Environmental Doom: The Power of the Mushroom

By Darren Chen and Allison Zhao, GRC 2023 Global Essay Competition Top 5

“We are on a pathway to global warming of more than double the 1.5-degree Celsius limit” (United Nations 2022). Many paths have been carved toward an increasingly sustainable future, and here we observe the enormous potential of something so tiny paving its own path to a net-zero, sustainable future: mycelium, a network of fungal threads (“Mycelium,” n.d.).

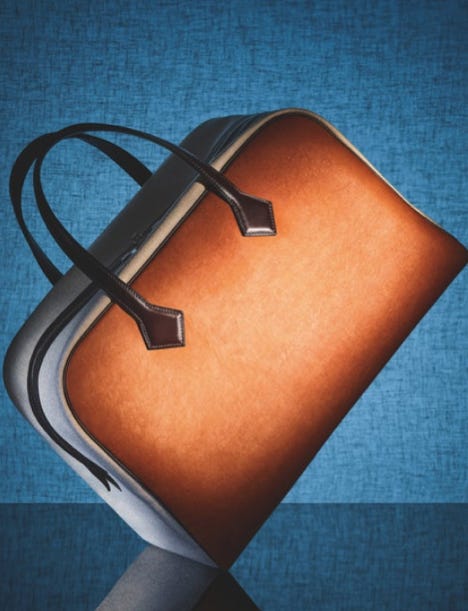

Researchers have been studying and developing new methods to enhance the heat-resistant, insulating, and durability properties of mycelium in order to make it into an all-purpose material like plastic. Considering the high potential of this material, several industries have explored the possibility of integrating mycelium into their products. A notable example is the mycelium-based Sylvania bag by Hermes (Vandelook et al. 2021, fig. 8), which demonstrated the strength and quality of mycelium products to the public. Mycelium also exhibits thermal-resistant properties “superior to other competing thermoplastic polymers” (Jones et al. 2018, sec. Conclusion).

With such properties, mycelium products can be the solution to net-zero buildings, climate change, and pollution if used appropriately. Firstly, mycelium insulation has comparable thermal conductivity to that of mineral wool (Sarkar 2015), meaning modern constructions can implement mycelium without compromising thermal performance. In addition, mycelium products can be used to construct temporary homes for refugees or disaster victims because of their affordability and sustainability—they happen to be 80 times cheaper than cement (Alemu, Tafesse, and Mondal 2022, sec. 2.1. Sustainable Materials). Mycelium bricks and mycelium products in general are biodegradable, thus reducing the carbon footprint of construction. Using mycelium as an alternative to tents or other forms of temporary shelter improves the quality of life while reducing the monetary and environmental burdens associated with current construction practices.

As global carbon levels rise, the need for more efficient carbon capture technology becomes increasingly urgent; without it, global temperatures will rise by 1.5 degrees Celsius by 2030 (“Scenario Trajectories and Temperature Outcomes – World Energy Outlook 2021 – Analysis - IEA” 2021), which will lead to irreversible environmental damage and societal destabilization (“Impacts of Climate Change | US EPA” 2023, Seeing the Impacts). Mycelium offers a promising solution, as it removes carbon from the atmosphere to build itself. By adopting mycelium as a construction material, we can capture carbon from the atmosphere and use it to replace other unsustainable materials. Statistics show that the production of biomaterials like mycelium can reduce carbon emissions by 800 million tons annually (Alemu et al., 2022). Currently, mycelium packaging serves as an eco-friendly alternative to Styrofoam, as it is lightweight and durable while being biodegradable (Alemu et al., 2022, p. Introduction). Replacing Styrofoam and other petroleum-based materials is the first step to reducing our fossil fuel reliance and creating a more sustainable future.

Despite mycelium’s many beneficial properties and versatile uses, with any new technology, research and development are required to fully understand the properties of mycelium so we can fully utilize it to replace current unsustainable materials, such as bricks. Bricks are mostly composed of finely grounded clay particles and some sand, often made by crushing clay using a jaw crusher, molded and then fired (“Brickhunter” n.d.). The firing step is the most environmentally detrimental step, as it burns carbon dense fuels. In India, brick kilns are responsible for two-thirds of the nation’s industrial black carbon emissions (Brownell 2023). Unlike the brick production process, the mycelium production process is low energy, low carbon emissions, and low cost (Alemu et al., 2022).

Mycelium cultivation technology is still in its infancy stage, and large-scale production proves to be difficult as there are large variations in compression strength between mycelium spores (Houette et al. 2022, sec. Compression Testing). Even with current limitations, mycelium’s applications are endless, ranging from load-bearing masonry components to cores for sandwich structures, and with technological improvements, mycelium can revolutionize the carbon-heavy construction industry (Ghazvinian and Gürsoy 2022).

Mycelium’s exceptional properties, especially biodegradability, make it an environmentally friendly choice compared to insulating foams, bricks, thermoplastic polymers, and plastic. Its durability, versatility, and affordability make it the optimal material for quick, temporary construction while offering great insulation and fire resistance. Furthermore, mycelium removes carbon from the atmosphere and turns it into a functional material, harnessing the power of pollutants. This emerging technology is one piece of the puzzle to fighting climate change and creating a sustainable future.

Bibliography

Alemu, Digafe, Mesfin Tafesse, and Ajoy Kanti Mondal. 2022. “Mycelium-Based Composite: The Future Sustainable Biomaterial.” International Journal of Biomaterials 2022 (March): 1–12. https://doi.org/10.1155/2022/8401528.

“Brickhunter.” n.d. Accessed December 10, 2023. https://brickhunter.com/blog/how-are-bricks-made.

Brownell, Blaine. 2023. “How Can We Reduce the Carbon Footprint of Bricks?” Architect. August 17, 2023. Accessed December 10, 2023. https://www.architectmagazine.com/design/how-can-we-reduce-the-carbon-footprint-of-b ricks_o.

F, James. 2021. “Hermès 101: Introducing ‘Sylvania’ Mushroom Leather - The Vault.” The Vault. June 9, 2021. Accessed December 10, 2023. https://www.rebag.com/thevault/hermes-101-introducing-sylvania-mushroom-leather/.

Ghazvinian, Ali, and Benay Gürsoy. 2022. “Challenges and Advantages of Building with Mycelium-Based Composites: A Review of Growth Factors That Affect the Material Properties.” In Fungal Biopolymers and Biocomposites, 131–45. Springer. https://doi.org/10.1007/978-981-19-1000-5_8.

Houette, Thibaut, Christopher Maurer, Remik Niewiarowski, and Petra Gruber. 2022. “Growth and Mechanical Characterization of Mycelium-Based Composites towards Future Bioremediation and Food Production in the Material Manufacturing Cycle.” Biomimetics 7 (3): 103. https://doi.org/10.3390/biomimetics7030103.

“Impacts of Climate Change | US EPA.” 2023. US EPA. November 29, 2023. Accessed December 10, 2023.

https://www.epa.gov/climatechange-science/impacts-climate-change#7foot.

Jones, Mitchell P., Tanmay Bhat, Everson Kandare, Ananya Thomas, Paul Joseph, Chaitali Dekiwadia, Richard K.K. Yuen, Sabu John, Jun Ma, and Chun H. Wang. 2018. “Thermal Degradation and Fire Properties of Fungal Mycelium and Mycelium - Biomass Composite Materials.” Scientific Reports 8 (1). https://doi.org/10.1038/s41598-018-36032-9.

“Mycelium.” n.d. Phaser App. Accessed December 10, 2023.https://www.micropia.nl/en/discover/microbiology/mycelium/.

Sarkar, Dipak K. 2015. “Steam Generators.” In Elsevier eBooks, 39–89. https://doi.org/10.1016/b978-0-12-801575-9.00002-0.

“Scenario Trajectories and Temperature Outcomes – World Energy Outlook 2021 – Analysis - IEA.” 2021. IEA. 2021. Accessed December 7, 2023.https://www.iea.org/reports/world-energy-outlook-2021/scenario-trajectories-and-tempera ture-outcomes.

United Nations. 2022. “UN Climate Report: It’s ‘Now or Never’ to Limit Global Warming to 1.5 Degrees.” UN News. May 18, 2022. Accessed December 9, 2023. https://news.un.org/en/story/2022/04/1115452.

Vandelook, Simon, Elise Elsacker, Aurélie Van Wylick, Lars De Laêt, and Eveline Peeters. 2021. “Current State and Future Prospects of Pure Mycelium Materials.” Fungal Biology and Biotechnology 8 (1). https://doi.org/10.1186/s40694-021-00128-1.